Robotiq User Conference – Quebec (4-5 September 2019)

Maria Osorio participated in the Robotiq User Conference RUC in the beautiful city of Quebec. This is our 1st conference on robots that we attended and we are very happy to have achieved it. The following writing is the summary prepared by María, with her notes and comments.

Cobot Stories – Cobot Stories from Factories | Samuel Bouchard

In the first conference, four business / industry cases that have incorporated the use of integrator robots were presented. In general, the call for the use of cobots was made in order to make «savings» in the respective companies. Yes, the investment in cobots can be $$, but in the long term the results in terms of production and profit are quite high. The four exhibitors were the following:

- Carlos Han: Smith and nephew, Mansfield. S&M is a global medical technology business, its main technologies have been concentrated in: orthopedic reconstruction, sports medicine, advanced wound management and external fixation (trauma). The cobots at S&M are in charge of doing “the dirty work” that is impossible for the hand of a realized human, hence their need to invest in cobots. The medicine sector, depending on the type of product, needs very high quality products and therefore it is a sector that is willing to invest in cobots.

- Jarek Hyjek: RBC Bearing Inc. An international manufacturer and distributor of high precision engineered bearings (bearings), they currently have 8 RU. They offer their products to two sectors: aerospace and industrial in various areas.

- Craig Zoberis: Fusion OEM (Cobotics-Assembly-Machining), Chicago. A company dedicated to the provision of manufacturing services to reduce costs, time and setbacks in production in X field. Zoberis, was the most passionate and motivated person for the use of Cobots within his company. Zoberis spoke about his difficult experience of starting to incorporate the use of Cobots but that in the end it is worth it, it seemed an interesting case to continue studying and / or taking an example. An interesting article on his company blog:

https://www.fusionoem.com/blog/cobots-working-hand-in-hand-with-humans

- From Procter and Gamble (P&G): it is a great industry, as we all know, so their investment in cobots has been quite large, their products will not stop being consumed, even if there is a crisis or whatever, and therefore it will always be an industry profitable to use cobots. On the Robotiq blog there is an article on how and why P&G came to the need for Cobots, see:

https://blog.robotiq.com/how-procter-and-gamble-lead-the-way-with-cobots

For the P&G engineer, it was important to maintain a “network” that would allow information on integrators to be disseminated and thus be able to work as a team. You have to build a team, of no more than two people, maximum three, for the management and education of the cobots. The important thing for all of them is «to start small, not to overcomplicate with the cobots and standardize the installation / preparation of the cobots.»

What’s new in Robotiq? | Jean-Philippe Jobin (Robotiq)

Under the motto of «free human hands» Jobin presented the advances of Robotiq:

- Stay involved in DoF: the Robotiq community providing a space to share experiences.

- Increase more in the “new / how”: through audiobooks, continue to evolve with the Elearning platform, the Robotiq configurator.

- Keep in mind: «a single tool for a specific case, and not a tool working for several things»

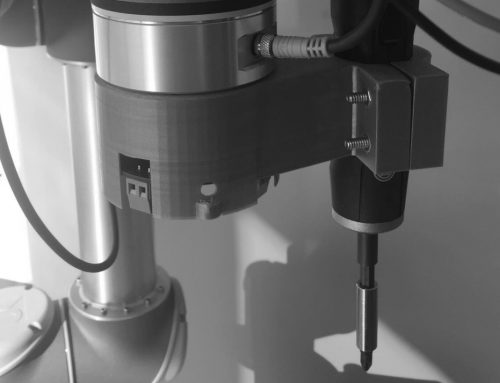

- Keep creating new software: example, the Machine Tending Kit.

- Updates of: Finishing Copilot and Wrist Camera URCap, especially for handling barcode reading. For Jobin, we must continue to focus on key Robotiq applications.

DIY or with a systems integrator?

In general terms, the use of cobots in the industry is still an unknown terrain, many industries that handle robots do not know about the existence of cobots and that is why they remain faithful to the use of robots, however, cobots is today a trend and therefore we must continue betting on this proposal to continue to meet the needs of future markets and customers. When starting out, you should focus well on a single integration system or choose different applications, but not too many. The next «industrial revolution» should be inspired by the union between man and machine and not separately, a «simple, dynamic, flexible revolution with adaptable production».

What’s new and not? Who is buying or not? Cobots + Business

This conference focused on thinking about the economic future of cobots and which ones. Currently, they are Robotiq’s clients, who and why those clients appeared and who would be the clients in the future. Keeping a vision on future markets, «investing in the future» is something they stressed a lot.

For Robotiq there are almost six industries that are considered «immune» that is, these industries have invested and will continue to invest in automation / cobots. These sectors are:

Automotive: it helps supply labor, and robots help humans to produce more in less time. Electronics: the demand for telephones, tablets, television, all kinds of “gadgets,” increasingly demand the use of automated robots.

Medical: the health sectors, biomedical, have benefited from cobots. Robots tend to be more precise for transporting drugs, particularly helping with surgery.

Welding: Although many of the welding processes require the human hand, many companies have started to make use of robots, Onken is one of them.

Food Services: some restaurants and food industries have also incorporated the use of robots for the large-scale production of their products.

Security agencies (law enforcement): military services, to dismantle bombs or other types of military or security devices.

Another sector Robotiq is trying to target is the Education and Government sector. Institutions or research centers, the academy in general seems to be a good bridge for the knowledge and use of automated robots, it is necessary to educate clients about the handling of robots. Robotiq already works with centers in Europe such as Kongsberg, Haw Hamburg, Hanzehogeschool Groningen.

Another sector that is nowadays in vogue is the Electrical Appliance sector (refrigerators, ovens, utensils, etc.) and Furniture, Ceramics, Plastics, waste industries, lens-glasses (the latter arose from the idea of a Japanese participant ), the Agroindustrial? … Furniture is particularly interesting for Robotiq since they offer polishing and finishing services, the handling of wood or metals lends itself very well to cobots. New markets must be «unlocked», without forgetting «old markets», and made to see that the use of automated robots can be a costly investment but that in the long term the results will be more than the cost of the investment. What are the industries today, for the Colombian case, that use automated robots? What has been your follow-up regarding the results and handling of them? Suddenly creating a rental system, cobot leasing? Which national or international industries, in Colombia, would be the most suitable for cobots? Are these industries aware of this, or are they still operating traditional robots?

It was a good conference to contextualize it in the Colombian and South American market. In Colombia, it is necessary to have a clear knowledge of the market. As they say, start simple in order to grow. In general, I could see that Robotiq has a lot of motivation, a lot of desire to continue growing and expanding.

Maria – 2019